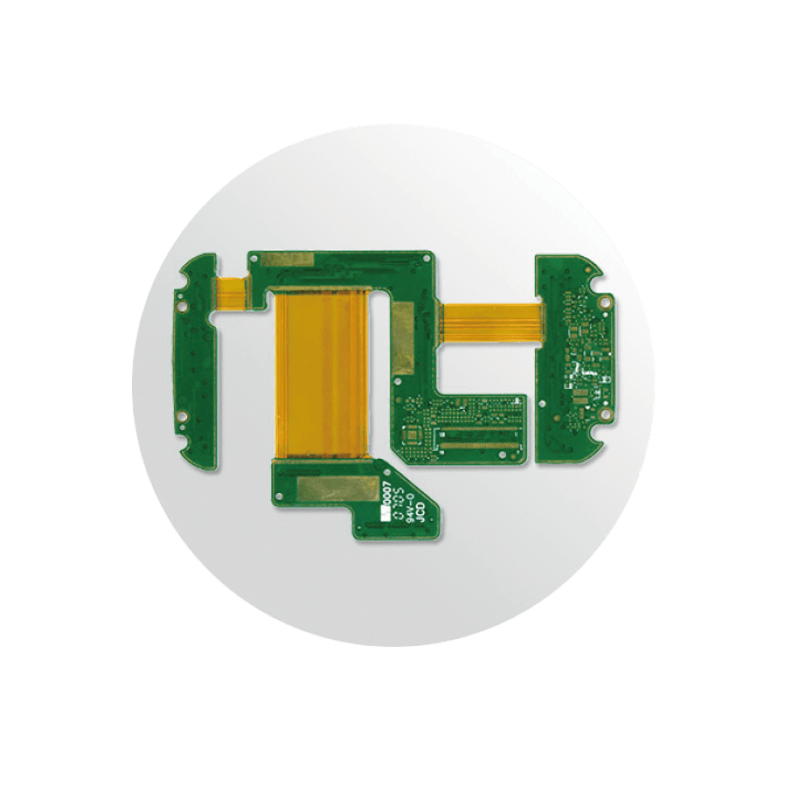

- Polyimide,Polyester,Adhesiveless technology

- Stiffener FR4,Polyimide

- ENIG (lmmersion Au), LF HAL,HASL, Immersion Sn, Immersion Ag, OSP

- Bond Au, Selective Au, Connectors. Buttons etc.

- Most of all colours of soldermask and legend

- Copper thickness from 12um

- Board thickness from 20um

- 1-4 layers

- Impedance control and verification

- CAM,DFM,Panel optimization, Product criticism

- Qc(Quality control) by Gscso with attached report document

- IPC Class ll and III

- FR4,Polyimide,Polyester,Adhesiveless technology, RCC

- ENIG(Immersion Au),LF HAL,HASL, Immersion Sn, Immersion Ag, OSP

- Bond Au, Selective Au, Connectors, Buttons etc.

- Most of all colours of soldermask and legend

- Copper thickness 18-500um

- Board thickness 0.012-6.0mm

- 1-40 layers

- Blind, buried, stacked vias

- Resin/copper filled blind via, sequential build-up

- Impedance control and verification

- CAM,DFM, Panel optimization,Product criticism

- Qc (Quality control) by Gscso with attached report document

- IPC Class ll and III

- FR4, High Tg, Halogen free

- ENIG (Immersion Au), LF HAL, HASL, Immersion Sn, Immersion Ag, OSP

- Bond Au, Selective Au, Connectors, Buttons etc.

- Most of all colours of soldermask and legend

- Copper thickness 18-500um

- Board thickness 0.2-6.0mm

- 1-44 layers

- Impedance control and verification

- CAM, DFM, Panel optimization, Product criticism

- QC (Quality control) by GSCSO with attached report document

- IPC Class II and III

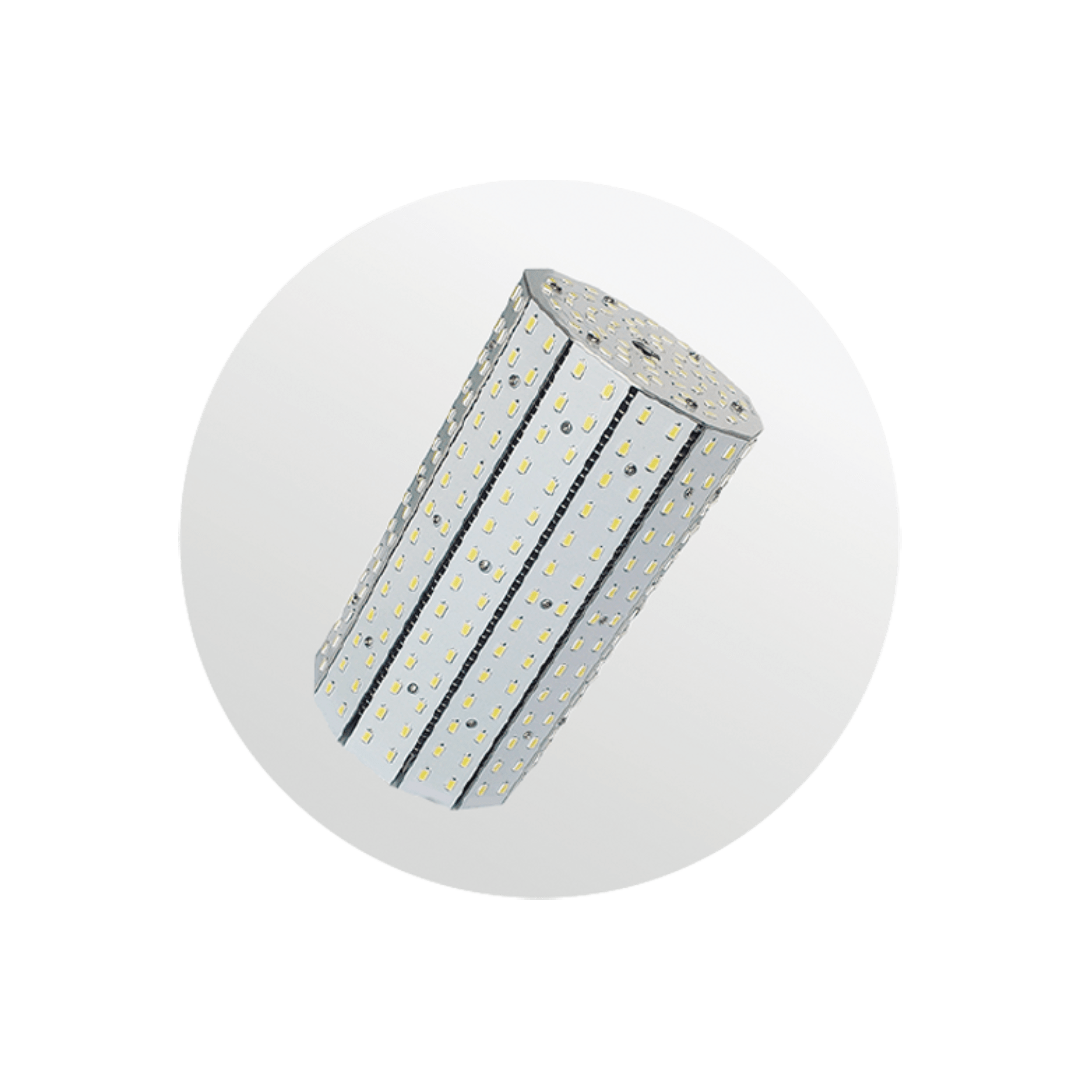

- Rogers, Bergquist, Arlon, Chin-Shi, Chaoshun etc.

- ENIG (Immersion Au), LF HAL, HASL, Immersion Sn, Immersion Ag, OSP

- Bond Au, Selective Au, Connectors, Buttons etc.

- Most of all colours of soldermask and legend

- Copper thickness 12-300um

- Board thickness 0.5-6.0mm (0.23 for UTC)

- 1-2 layers

- CAM, DFM, Panel optimization, Product criticism

- QC (Quality control) by GSCSO with attached report document

- IPC Class II and III

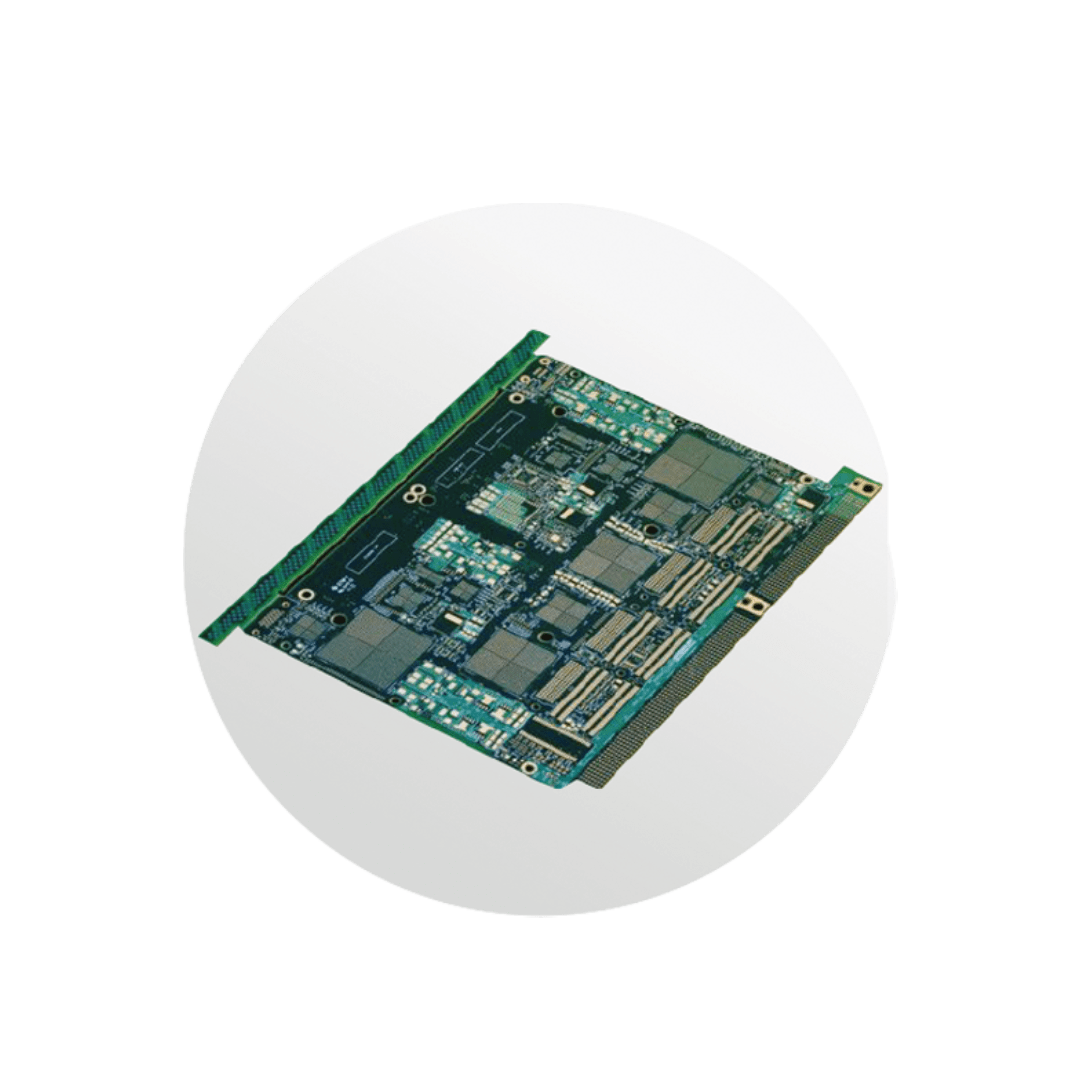

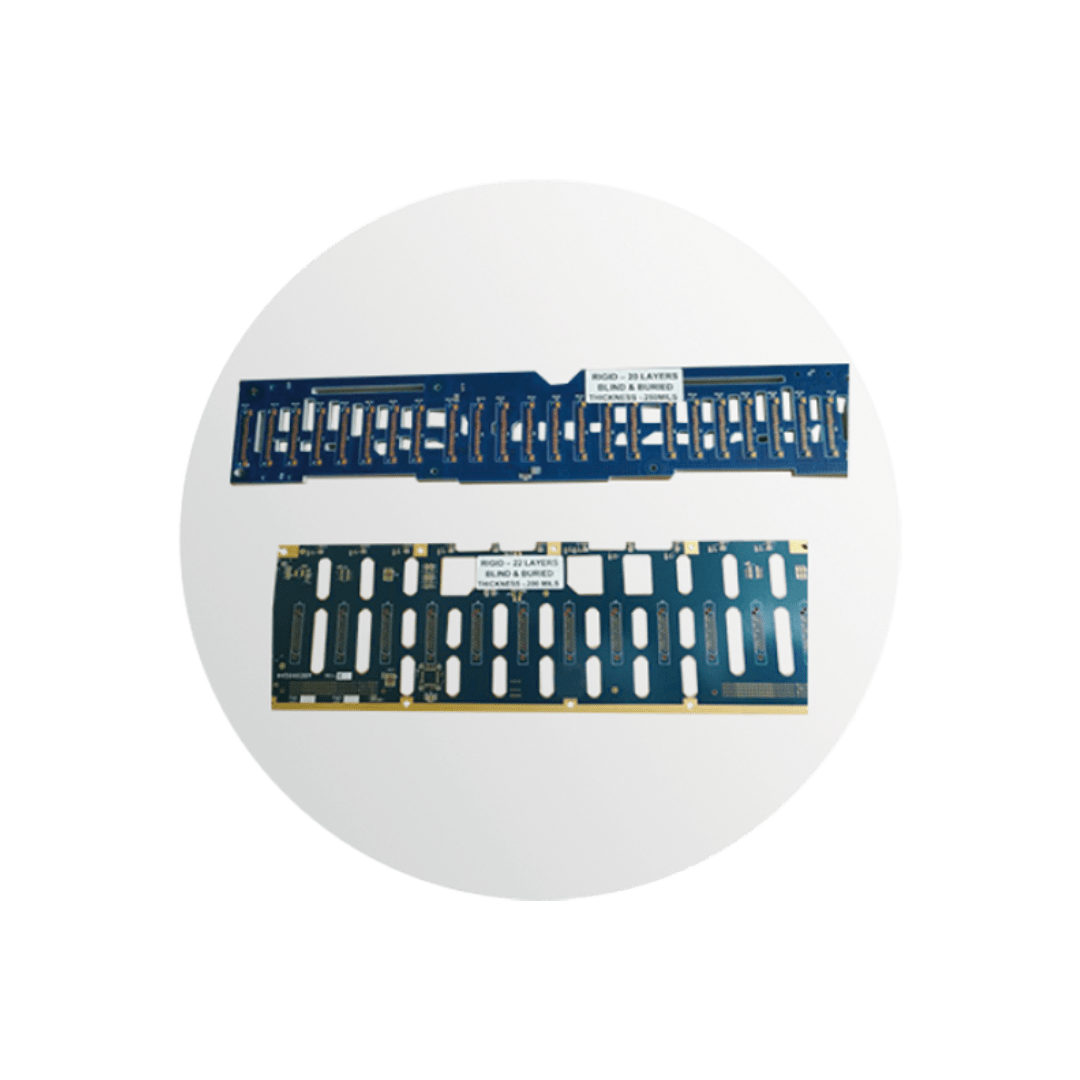

- FR4, High Tg, Halogen free, RCC-foil

- ENIG (Immersion Au), LF HAL, HASL, Immersion Sn, Immersion Ag, OSP

- Bond Au, Selective Au, Connectors, Buttons etc.

- Most of all colours of soldermask and legend

- Copper thickness 18-500um

- Board thickness 0.3-6.0mm

- 4-40 layers

- Blind, Buried, Stacked vias and back drilling

- Resin/copper filled blind vias, sequential build-up

- Impedance control and verification

- CAM, DFM, Panel optimization, Product criticism

- QC (Quality control) by GSCSO with attached report document

- IPC Class II and III

- On the market used materials, Rogers, Neltec, Arlon, Taconic etc.

- ENIG (Immersion Au), LF HAL, HASL, Immersion Sn, Immersion Ag, OSP

- Bond Au, Selective Au, Connectors, Buttons etc.

- Most of all colours of soldermask and legend

- Copper thickness 18-500um

- Board thickness 0.2-6.0mm

- 1-20 layers

- Blind, buried, stacked vias

- Resin/copper filled blind via, sequential build-up

- Impedance control and verification

- CAM, DFM, Panel optimization, Product criticism

- QC (Quality control) by GSCSO with attached report document

- IPC Class II and III